For the TRIUMF team, it was both exciting and nerve-wracking to watch their first completed Inner Tracker “petal” – a delicate construct of silicon sensors, carbon fibre and electronics, assembled partially by precision machines and partially by the skilled hands of technicians – depart for Diamond Light Source in Oxfordshire, England. It left Vancouver wrapped in layers of protective foam and accompanied by reams of paperwork.

Though the shipping process is rigorous and well-defined, it is still a tense experience for the project team.

“We did everything we could to make extra-sure it didn’t arrive in more pieces than it was shipped!” said Dr. Luise Poley, TRIUMF Project Scientist.

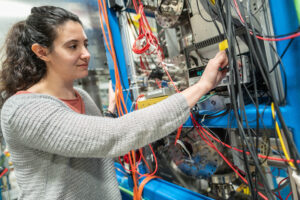

(image: Emily Filmer, TRIUMF Postdoctoral Researcher, with the completed Inner Tracker petal at Diamond Light Source)

That petal, built at TRIUMF and Simon Fraser University (SFU) detector facilities, was bound for a compact testing room within Diamond’s B16 beamline and downstream of its synchrotron particle accelerator. There, under the pinpoint focus of an x-ray beam approximately one-tenth the size of a human hair, the structure underwent its first major validation, which serves to verify the wider production process and brings the team one critical step closer to embarking on the construction of 100 such petals for the ATLAS detector at the Large Hadron Collider.

Watching the beam skim across the surface, Poley and colleagues Matt Basso (TRIUMF), Emily Filmer (TRUMF) and Dennis Sperlich (University of Freiburg) saw months of painstaking effort pay off.

“It was amazing to see all of our hard work validated in real time,” said Poley. “While each petal undergoes multiple quality control procedures, this test at Diamond was the final confirmation that all the individual parts – tapes from Slovenia, carbon cores from Spain, sensors from Japan, modules from Canada – fit together and function as intended and have the alignment precision they are meant to have. It’s a single test to confirm that all petals should function as designed.”

Inner Tracker upgrades for the next era of ATLAS science

Canada’s connection to the ATLAS detector stretches back to the early 1990s, to before Canada officially joined the LHC collaboration in 1996. Since then, Canadian researchers have been leading or supporting in a variety of capacities, including designing, building, operating and maintaining the massive detector.

Now, through TRIUMF, Canada is helping to rebuild it. The upcoming High-Luminosity LHC (HL-LHC) will deliver more collisions and more radiation than ever before, and the existing tracking system must be replaced with something entirely new: the Inner Tracker, or ITk.

TRIUMF is one of four main sites worldwide fabricating “petals” for the ITk endcaps (large discs that cap either side of the barrel-shaped ATLAS detector) alongside partners in Toronto and Spain.

In total, Canada is responsible for approximately 1,500 of the 7,000 silicon strip modules that will make up the end-cap system; with the strip sensors in the main horizontal barrel, the Inner Tracker will total 18,000 sensor modules covering 160 m2.

Each sensor is unthinkably delicate: strips just 75 microns wide and 25 millimeters long register the passage of subatomic particles, allowing researchers to trace their paths with exquisite precision. Further, each petal comprises six unique sensor geometries, leading to six different module types. Assembling them into uniform, reliable petals requires exacting standards – and deep collaboration.

“With all of the various production sites, there are so many different groups working across so many countries that need to interface to be able to produce these petals, all of which need to be designed and manufactured to be exactly the same,” said Poley. “So, part of this success is also a validation of our ability to work collaboratively across borders.”

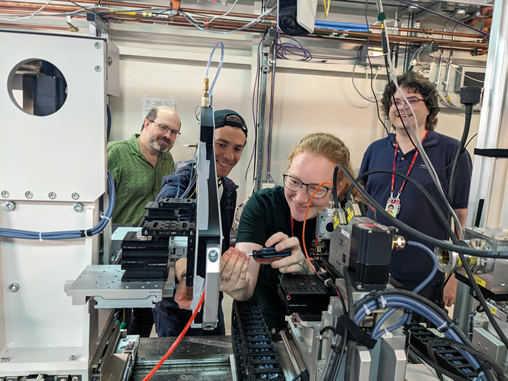

(image: Poley, left, and Dennis Sperlich adjust the petal)

At Diamond Light Source, TRIUMF’s petal was put through its paces. Only select regions could be tested – the beam is so fine that scanning the entire petal would take more than a year. However, even those checks were enough to confirm crucial details: alignment, dimensions, and the hermetic coverage needed to ensure that no particle of interest goes untracked as it travels through metres of some of the most extreme radiation environments ever produced in a scientific experiment.

The success is a testament to TRIUMF’s strong connections to European science infrastructure and the international physics community and leveraged contributions from Diamond Light Source (which provided in-kind support with six valuable days of beamtime), the University of Freiburg, and colleagues at the Rutherford Appleton Laboratory (RAL) in the UK.

(image, from left: Dr. Bruce Gallop (RAL), Basso, Filmer, and Sperlich)

With the validation complete, teams from TRIUMF and SFU are now looking ahead to production at scale. The goal is to establish a workflow capable of producing two modules per day, supporting a production cadence of three petals per month for the next three years.

The journey of a single petal, carefully packed and shipped across the Atlantic, is only one small chapter in a vast global project. But for the joint TRIUMF/SFU team, seeing it withstand the scrutiny of Diamond Light Source beam was a powerful reminder of why the years of effort matter. Each successful test brings ATLAS one step closer to being ready for the HL-LHC, and one step closer to the new discoveries it promises to reveal.