The issuance and standing of TRIUMF's operating license is determined by the Canadian Nuclear Safety Commission (CNSC). As a natural part of this process TRIUMF undergoes inspections of many of its activities. For instance, CNSC regularly sends a team of specialists to TRIUMF to inspect the laboratory's Quality Management System and evaluate its effectiveness. The inspection process takes about a week and completes with a debriefing and written report. This year, 3 quality assurance auditors arrived at TRIUMF's facilities on March 9th and were welcomed by the Director, Dr. Nigel Lockyer and Dr. Don Brooks, a member of TRIUMF's Board of Management and the UBC Associate Vice President of Research.

Moving beyond past experiences, TRIUMF's attitude for this review was more engaging and integrative than previous years. Employees made an effort to show the lab as a whole by publicizing the audit around the site and raising awareness through bulletins such as Quality Times. All members of the TRIUMF community were invited to attend the presentations and be part of this open process.

Dr. Brooks started the first morning with an explanation of the governance structure of TRIUMF. Dr. Lockyer continued with the functional structure and explained the roles and responsibilities of the various committees that ensure the smooth operation of the laboratory. Other TRIUMF staff gave presentations covering such topics as purchasing, work permits, design, and records management. Throughout these sessions, the auditors asked probing questions and identified areas where further investigation would be needed.

After the presentations, the auditors visited different areas of TRIUMF to meet the groups and review some of their records. Their investigation was primarily "fact-based," meaning that if TRIUMF's QMS states that a specific process is in use, then TRIUMF must also be able to present evidence to that effect. An example of this is the database maintained by the Mechanical Systems Group to track periodic calibration of ventilation system devices. The auditors would check to see if there is a plan in place to enforce this and to collect records of the calibrating dates, the measurements, resource used, etc. Another example is verifying that assessments of hazards associated with different tasks are accurate and complete. At the end of the week, the auditors submit their observations. During this review, they expressed satisfaction with the planning and execution of the Quality Management System. While not all activities were up to their desired standard, some were exemplary. Ken Buckley, PET Engineer at TRIUMF explains, "Although there is still room for improvement, it was good to obtain feedback and know we are on the right track. We have to seize this momentum, keep the implementation moving and maintain progress."

TRIUMF acknowledges everyone who participated in the preparation for this audit and congratulates the staff's efforts to ensure positive results.

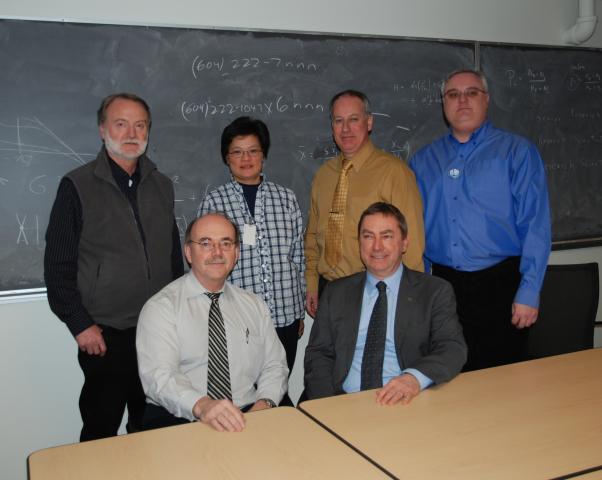

Director of TRIUMF, Nigel Lockyer and CNSC Audit Group

By Maria Jose Crousillat

Based on "Waiting for our Audit Report Card" by Ken Buckley