TRIUMF now has a bright, shiny, and new main injection line. The line is used to transport hydrogen ions from the ion source to the centre of the cyclotron. The previous injection line had been in use for 37 years, since the cyclotron first produced beams in 1974. As the years have been adding up on the old line, the carbon on the ceramic insulators used to ground the beam line and exposure to radiation levels during cyclotron operation has slowly been damaging the network of cables that support the beam line. Over the past few years, TRIUMF has set out to design, develop, build, and then install a sophisticated replacement for the cyclotron’s injection line. The key section of the injection-line replacement is the vertical section. The TRIUMF team working on this project took this opportunity to enhance the injection line’s performance and functionality. Physicists and engineers redesigned the beam line using more robust transport optics and added more diagnostic capabilities so that operators have better knowledge of the beam’s intensity, size, and position as it is injected into the centre of the cyclotron. These measurements can be taken in two ways – the first being interceptive where the monitor crosses the beam, interrupting it to record data. The second way is observational where the device scans the beam without directly interact with it. Before installing the redesigned beam line, the team had to remove the old beam line including hundreds of cables, water lines, heating lines, and other elements from within its narrow home. Once removed, with all of the elements carefully disposed of the installation of the new beam could commence! The new beam line has been installed in four sections; the first was installed in September 2009. This was done as validation for the new design, including new features, which were then tested over one and a half years. Some areas for improvement were revealed, and the team incorporated these changes into the vertical section. The next step was to install the lower section of the vertical beam line. There is not enough space between the overhead cranes and the top of the cyclotron to directly lower the vertical beam line into place, so both cranes were needed to hold a special support structure that could carry the beam line by a precision hoist. This allowed the engineers to lower it into position. Installation occurred without at hitch and by 10:30am January 27 it was in place. The team then commenced a series of tests such as a vacuum test to check for leaks, an electrical test to check that the signals were as to be expected, and a diagnostic test to ensure that the monitors and controls were working correctly. After a few complications with physical alignment, the last piece of the vertical beam line was in motion at 8:00am last Tuesday. The same checks as with the previous section were made, but as this section was even longer than the last one, maneuvering and installing this last section gave the engineers a challenge. Even though it was close quarters, they successfully transported and installed the section at 9:00am. Congratulations and a huge thank you to Roman Reugg and his team for their hard work and dedication in this process. Successfully completing this installation with an accelerated schedule was a tremendous accomplishment.

-- Lindsay Davies, Communications Assistant |

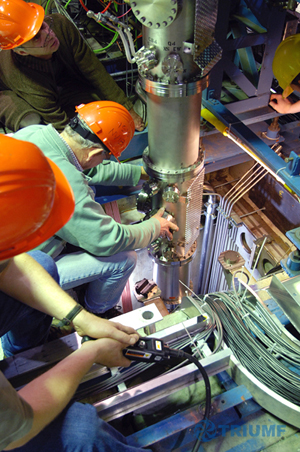

Close-up shot of the installation. |

Canada's particle accelerator centre

Centre canadien d'accélération des particules

Centre canadien d'accélération des particules