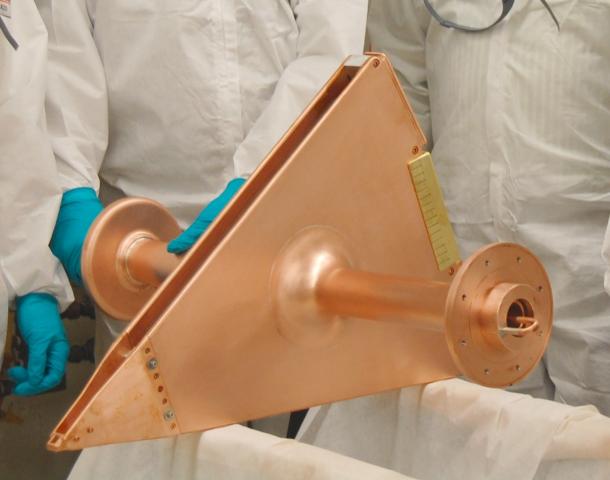

One of Nordion’s three medical isotope cyclotrons has been given a new lease on life thanks to a pair of dees and a fantastic team. The TR30-1, which is located at TRIUMF and operated by the ATG group for Nordion, is finally coming up to full speed after being out of service for more than a month. Dees are the main components of the radio frequency (RF) resonators. They are responsible for accelerating H- ions at 50 kV, within a 73 MHz alternating field. After more than 20 years in operation and attempted repairs, the cooling lines of the TR30-1’s dees were showing leaks and complete replacement was deemed necessary. The ultimate, yet difficult goal is to achieve full recovery of the machine's performance after replacement. The carefully scripted process began with electrical measurements to determine the RF parameters of the system under various conditions. After the parts were manufactured at Advanced Cyclotron Systems, Inc. (ACSI) in Richmond and delivered on site, the exchange of the mechanical components was much like a simple swap, albeit requiring great precision. More RF measurements and initial tuning followed. The real hurdle came after installation – conditioning and operational tuning. Conditioning involved bringing the RF parameters in the tank up to normal running conditions under vacuum. Raising the voltage to 50kV in the newly installed dees was significantly complicated by multipacting, caused by secondary electron emission and outgassing from surfaces and gases trapped within the tank. Coating all surfaces reduced some of the effects, however, increasing RF voltage too soon may still have produced enough electrons to result in an electrical short. Resultantly, Jozef Orzechowski noted that, “Conditioning had to be done gradually.” Conditioning is alternated with operational tuning. Within the cyclotron, power is transferred through the use of RF coupling, where a specific frequency is best for optimal machine performance. During the replacement process, the minute changes in manufacturing and assembly were huge enough such that simply relying on the frequency used with the old dees did not yield optimal machine performance. Operational tuning reestablished this nominal frequency. It took a team of five, working full time for over a month, to bring the machine up to speed. As complicated as the process was, it was made a little easier through TRIUMF’s partnership with ACSI. Not only did it help resolve problems relating to the manufacture of the dees, it also contributed qualified personnel to the team that undertook the replacement. The symbiotic relationship exists beyond this event. Each week, the three Nordion cyclotrons are capable of supplying nearly 45,000 patients with medical isotopes. This is a prime example of how the technological knowledge within TRIUMF is being transferred to the private sector, where it can benefit the greater community. More than maintenance, this has been a learning experience - “For this type of machine, for both ACSI and TRIUMF, it’s the first time this kind of major maintenance has been performed on any TR30,” said Gabriel Cojocaru. Just another way in which TRIUMF is leading the way in technological progress.

--Written by Lena Sitnikova, Outreach Assistant |

|

|

| ||

|

|